AATCC 30

Antifungal Activity, Assessment on Textile Materials: Mildew and Rot Resistance of Textile Materials

Home >> Antifungal >> AATCC 30

AATCC 30 – Antifungal Textile Test

AATCC 30 is a standard protocol that determines the efficacy of textile materials impregnated with fungicides. The antifungal finishes are applied to textiles to give the material protection against mildew and rot.

AATCC 30 test method can be used for all these textile materials including cotton, rayon, nylon, silk, wool, linen, polyester, co-acrylic, spandex, viscose, sandbags, tarpaulins, tents, etc.

Organisms typically used in this method: Aspergillus niger (ATCC-16888)

Types of AATCC 30 Test

Depending on the type of textile materials and their intended use, AATCC – 30 standard protocol uses 4 different types of test methods –

AATCC 30 Test I – Soil Burial test method

It is used for textile materials that tend to come in contact with soil. Sandbags, tarpaulins, and tents are the main textile products to be tested using this test method.

Test procedure

- To make the soil bed, air-dry test soil is put in suitable containers (boxes or trays) with a depth of 13.0 ± 1.0 cm. After that, water is gradually added here to bring optimum moisture content and sieve with a mesh screen. This is allowed to stand for 24 hrs.

- Both the untreated and treated textile samples (of a specific size) are exposed in the soil beds for 7 days to determine the fungal activity.

- After the incubation period, textiles samples are removed, washed with water, and air dried at room temperature for 22 ± 4 h. Further, put in an atmosphere of 64 ± 2% humidity and a temperature of 24 ± 3°C (76 ± 6°F) for the next 24 hrs.

- The breakage strength of the treated fabric is compared with the control (untreated) sample and pre-exposed specimens before burying.

AATCC 30 Test II – Agar Plate, Chaetomium globosum

This test method is used to assess the rot resistance of cellulose-containing textile materials that do not come in contact with soil

Test procedure

- Test (treated) and control (untreated) samples are placed on mineral salt agar medium.

- 10-14 days old test inoculum of Chaetomium globosum is evenly distributed over the test sample using a sterile pipette. While sterile water is added to untreated samples.

- After a specific incubation period, treated fabric samples are evaluated for their breakage strength and antifungal resistance.

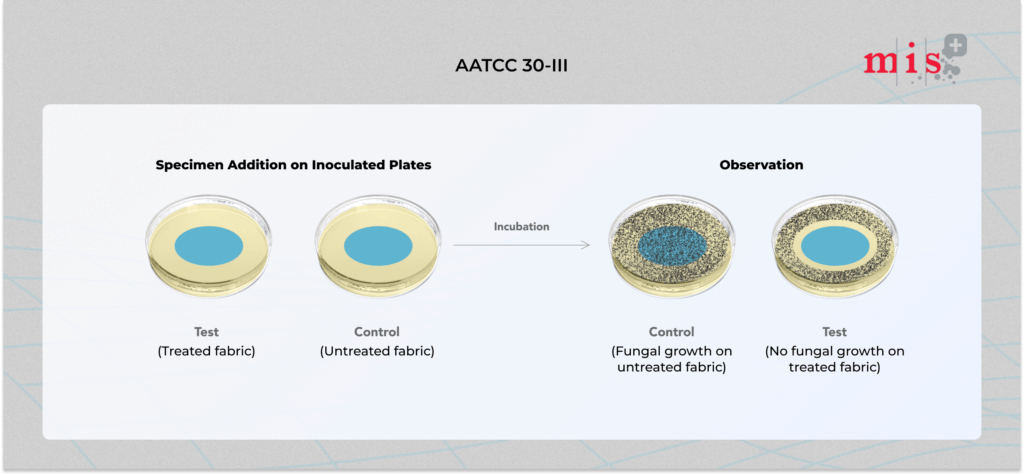

AATCC 30 Test III – Agar Plate, Aspergillus niger

This test is used to evaluate the efficacy of treated textile materials against the growth of the fungus, Aspergillus niger.

Test procedure

- Test (treated) and control (untreated) specimens are placed on the sterilized mineral salt agar medium.

- 7-14 days old test inoculum of Aspergillus niger is evenly distributed over the test and control samples by using a sterile pipette.

- All the samples are incubated at a temperature of 28 ± 1°C for 14 days.

- After the incubation period, results are evaluated through the microscopic examination of fungal growth on samples.

AATCC 30 Test IV – Humidity Jar, Mixed Spore Suspension

This test method is designed to determine the efficacy of textile materials to control mildew and non-pathogenic fungal growth. This test is applicable for waterproof textile material intended for outdoor and above-ground use.

Test procedure

- Treated (control) and untreated (test) samples are fabric placed in their respective jars and sprayed with a mildew spore suspension.

- These samples are incubated for 14 – 28 days and are weekly evaluated for fungal growth.

At Microbe Investigations, we run antifungal activity assays on treated textiles and plastic materials used for daily activities, industrial purposes, and other areas susceptible to fungal growth. Our experts adhere to International Standards for achieving reliable, accurate, and reproducible results.

To get a quote on AATCC 30 test and other related queries, get a free consultation from our expert here.

FAQs

AATCC 30 test is a standard protocol used to evaluate the mildew and rot resistance of textile material. AATCC 30 employs 4 different types of test methods, depending on the type of textile materials and their intended use.

AATCC 30 test is applicable to different types of materials including cotton, rayon, nylon, silk, wool, linen, polyester, co-acrylic, spandex, viscose, sandbags, tarpaulins, tents, etc.

AATCC 30 test takes 4-5 weeks to complete.

At Microbe Investigations, we understand the need for accuracy and speed. We test for AATCC 30 using Aspergillus niger (ATCC-16888).

Contact us for more information

Explore Other Tests

ASTME2149 | AATCC-100 | JISZ2801 | JISL1902 | EN 1276 | ISO 22196 | ISO 20743 | ISO 846 | ASTM E2180 | AATCC 147 | ASTM D7907-14 | ASTM E3031 | ASTM G29 | EN 16615 | EN 13697 | PAS 2424 | EN 1040 | EN 14349 | EN 13727 | EN 14561 | ASTM G22 | ASTM E1153 | ASTM D2574 | AATCC 174 | EN 14563 | EN 13704 | EN 1499 | EN 1500 | EN 14347 | EN 14348 | EN 1656 | EN 16437 | EN 12791 | ASTM E1174 | ASTM E2362

AATCC 30 | ASTM G21 | EN 1650 | EN 1657 | EN 13624 | EN 1275 | ASTM C1338 | ASTM D5590